Introduction

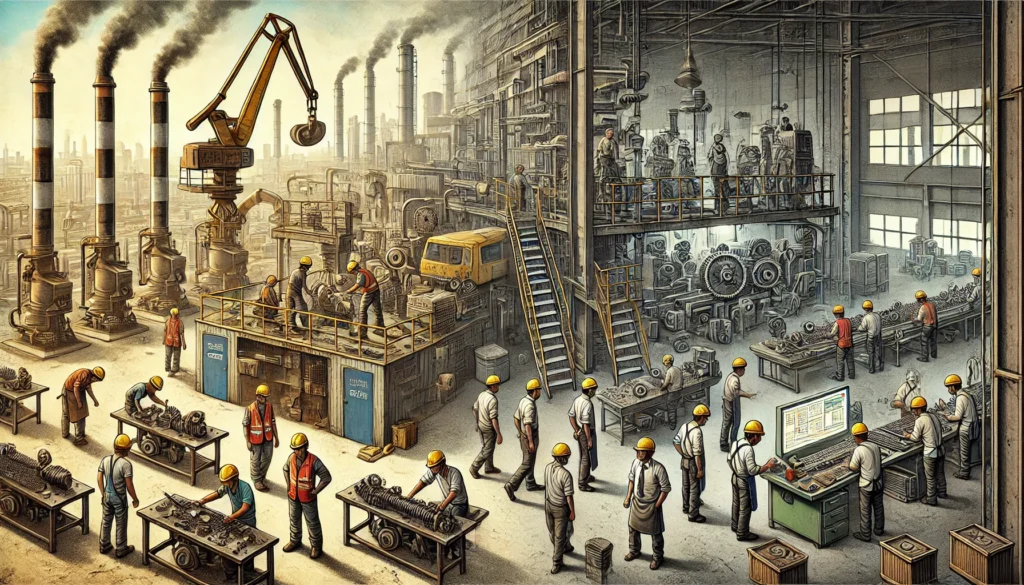

India’s manufacturing sector is a vital driver of economic growth, contributing significantly to GDP and employment. With the rise of initiatives like Make in India and Atmanirbhar Bharat, the demand for a skilled blue-collar workforce has never been greater. However, ensuring both skill enhancement and workplace safety remains a challenge. Addressing these issues is crucial for improving productivity, reducing workplace accidents, and creating a globally competitive manufacturing sector.

The Importance of Blue-Collar Workers in Manufacturing

Blue-collar workers form the backbone of India’s manufacturing industry, engaging in various roles such as machine operation, welding, assembly, and logistics. Despite their importance, they often face unsafe working conditions, lack of proper training, and job insecurity. Without strategic intervention, these issues can lead to high attrition rates, reduced efficiency, and increased workplace incidents.

Challenges in Workforce Safety and Skill Development

1. Workplace Safety Issues

Many Indian factories and industrial plants suffer from inadequate safety measures. Common problems include:

- Lack of proper safety gear

- Poor enforcement of workplace safety regulations

- Outdated machinery prone to malfunctions

- Insufficient knowledge about hazardous materials

According to the National Crime Records Bureau (NCRB), thousands of industrial accidents occur annually due to these factors, leading to injuries and fatalities.

2. Skill Gaps and Training Deficiencies

Another major challenge is the lack of access to quality training programs. Many workers enter the manufacturing sector with minimal formal training, relying on outdated or inefficient methods. The key issues include:

- Limited vocational training institutes

- Outdated curriculums that do not align with modern manufacturing needs

- Lack of digital literacy, affecting workers’ ability to adapt to automation and AI-driven processes

3. Job Insecurity and Informal Employment

A large portion of India’s blue-collar workforce operates in the informal sector, lacking social security benefits, health insurance, or job stability. This lack of security discourages workers from investing in skill development, as they are unsure about long-term employment prospects.

Strategies for Building a Safer and More Skilled Workforce

1. Strengthening Workplace Safety Regulations

To ensure safer working environments, manufacturing companies and policymakers must collaborate on enforcing strict safety regulations. Key measures include:

- Mandatory Safety Training: All workers should undergo safety training before starting their jobs.

- Provision of Safety Gear: Employers must ensure workers have access to protective equipment like helmets, gloves, and goggles.

- Regular Safety Audits: Companies should conduct frequent safety inspections and address any lapses immediately.

- Use of Technology for Safety: Wearable technology, such as smart helmets with sensors, can help monitor worker safety in real-time.

2. Enhancing Skill Development Programs

Investing in training initiatives is crucial to bridging the skill gap. This can be achieved through:

- Public-Private Partnerships (PPP): Collaboration between the government and industry leaders can result in better vocational training programs.

- Modernizing ITIs (Industrial Training Institutes): Updating curriculums to include automation, robotics, and AI-based manufacturing processes.

- On-the-Job Training: Companies should implement structured training programs that allow workers to learn while they work.

- E-learning and Digital Tools: Using mobile-based learning platforms to make training more accessible to workers in remote areas.

3. Providing Social Security and Job Stability

Ensuring financial and social security will motivate workers to upskill and stay in the industry. Measures include:

- Introducing Health and Life Insurance Schemes: Companies should offer basic insurance coverage for workers.

- Encouraging Formal Employment: Employers should be incentivized to shift more workers from informal to formal employment contracts.

- Skill-Based Certification Programs: Recognizing workers’ skills through certification can improve their employability and wage prospects.

Role of Government and Industry in Workforce Development

The government has taken various initiatives, such as:

- Skill India Mission: Aims to provide vocational training to millions of workers.

- National Apprenticeship Promotion Scheme (NAPS): Encourages companies to hire and train apprentices.

- OSHA-style Safety Regulations: Proposing stricter workplace safety laws modeled after international standards.

Manufacturing companies must also take proactive steps, such as establishing in-house training centers, partnering with ITIs, and leveraging Industry 4.0 technologies for upskilling.

The Future of India’s Blue-Collar Workforce

As India advances towards becoming a global manufacturing hub, the emphasis on safety and skill development will play a crucial role in shaping the future workforce. Adoption of automation, AI, and smart manufacturing will require workers to be adaptable and continuously upskill. Governments, industry leaders, and educational institutions must collaborate to build a robust and resilient workforce.

Conclusion

Building a safer, more skilled blue-collar workforce in India’s manufacturing sector is essential for the country’s economic growth and global competitiveness. By focusing on workplace safety, investing in skill development, and providing job security, India can ensure a thriving and sustainable manufacturing industry. The time to act is now—implementing these strategies will not only benefit workers but also contribute to the overall success of the sector.